Would you like to be kept informed of developments?

In our free white paper, we share information about the new rules of legislation, innovations in analysis and we tell you about the digitisation of the market. Download our white paper for free!

Analysis Selector

Analysis Selector

Having the right mix of raw materials is essential for producing a homogenous product. During the production process cross-contamination takes place. The process of dosage, mixing and transporting the mixture is generally the primary source of cross-contamination. The homogeneity and cross-contamination of a production line is tested using microtracers. Therefore, it is vital that sample collection at critical points in the system takes place. Nutrilab has substantial experience in setting up and executing microtracer tests for feed and dried goods production-line monitoring. The most significant advantage of the MTSE microtracer procedure is that test batches do not need to be destroyed afterwards. For feed applications, standard production batches can be delivered straight to your customers.

In determining homogeneity and cross-contamination using the MTSE microtracer method, Nutrilab provides project guidance for on-site sample collection upon request. Nutrilab is the only Dutch laboratory licensed to do so on behalf of Micro Tracers Services Europe (MTSE) in Germany. With extensive experience with a large number of production companies, Nutrilab has the expertise to advise and assist with the execution and sample collection process.

The MTSE method tests homogeneity and cross-contamination at a very detailed level. This is the level at which trace elements and antibiotics are found: 10 grams per 1000 kg, or a mixing ratio of 1:100,000. For premix lines and pharmaceutical mixers, the method is technically capable of measuring ten times that level of detail, 1 gram of microtracers per 1000 kg of product or a mixing ratio of 1:1,000,000. A few grams of microtracers are packaged in a premixed form with an inert carrier, usually calcium carbonate or a product-specific carrier upon request. The production batch determines the amount of premixed material.

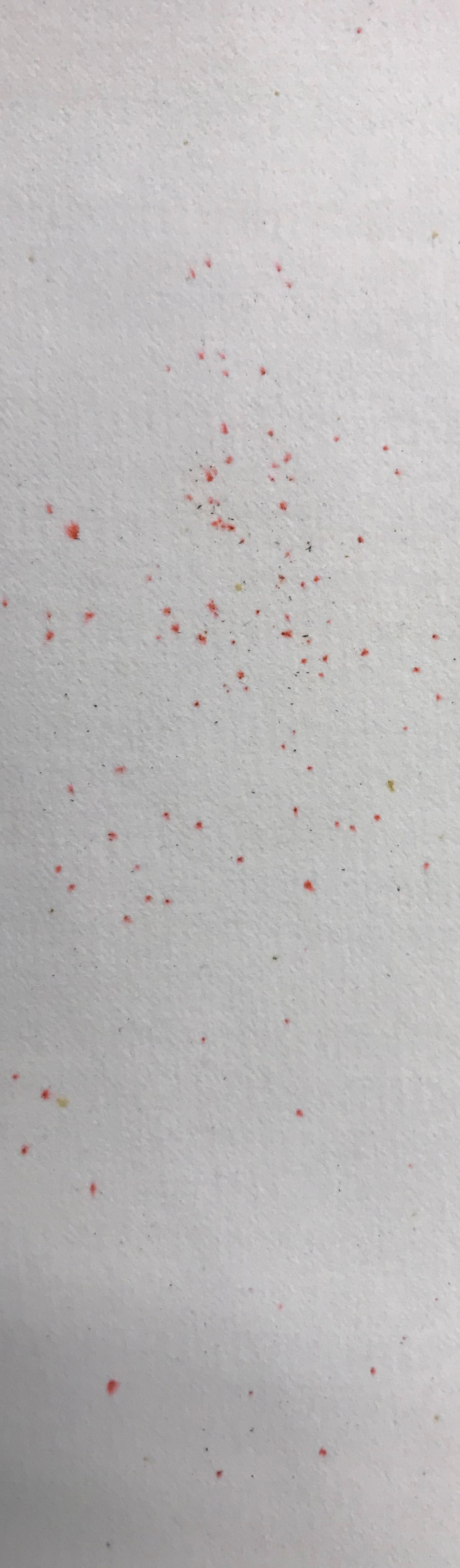

The low dosage provides a significant advantage in determining the homogeneity of feeds. The testing method is realistic and can provide ample information about the mixing process. This method also has the possibility of validating the mixing time of mixers. This process involves different coloured microtracers, which are added to the mixer at different times, allowing validation of the mixing time in a single test batch. After the sample collection, the samples collected from the test batch are analysed at the Nutrilab laboratory for several microtracers. This analysis can be carried out on one or several coloured microtracers and concerns a direct count of the number of microtracers in the product. The homogeneity is calculated using the Poisson distribution.

The microtracers are composed of inert iron particles which cannot be absorbed organically. These iron particles are coated with a food-grade, coloured coating and can immediately be distinguished from uncoated iron particles from machines and raw materials during analysis in the laboratory. For this purpose, a specially coloured developing liquid is used during the analysis. Iron particles from machines and raw materials are not coated and will, therefore, not generate coloured spots in the analysis. In contrast to some older microtracer methods, no control batch needs to be produced and sampled as a comparison.

In microtracer testing, the first batch is used for determining the homogeneity, and he second batch is used for determining cross-contamination levels. With one microtracer premix, it is possible to take additional samples at critical points in the process and keep these in stock for further testing should the end products deviate in any way.

We will be happy to visit you to discuss any quality questions or issues you may have.

Plan an advisory meeting

In our free white paper, we share information about the new rules of legislation, innovations in analysis and we tell you about the digitisation of the market. Download our white paper for free!

Powered by Wallbrink Crossmedia